Material and Spare Part Management

ACEC manages autonomously and with full responsibility, all Materials associated with the execution of any work. ACEC’s responsibilities will include but will not be limited to the procurement, handling and storage of spare parts for utilities and facilities and consumables for operation.

As a minimum, ACEC will:

- Ensure adequate organization structure for Materials Management

- Provide computer based system(s) to support the materials management process — procurement, financial matters, stock control and warehouse management

- Prepare a complete coded list of Spare Parts and incorporate an asset tag management system

- Identify the Materials that are readily available from the local market and those have long delivery time

- Set stock levels for all materials.

ACEC’s model for spare parts market analysis includes:

- Procuring in advance the long lead items and storing them in a storage room to maintain the minimum stock level deemed necessary

- Promptly replacing any material utilized for maintenance needs in order to respect the stated minimum level of stock

- Procuring the Spare parts and consumables

- Arranging any necessary import authorization — both temporary and permanent

- Storing, supplying and managing the spare parts, lubricants and consumables — including those required for the operability of their tools, such as drills, test instruments and vehicles/cars

Following this process, ACEC will optimize and manage the spare parts analyzed. All spare parts for preventive maintenance will be supplied by us and included in utilities operation and maintenance Work on cost plus 7.5% basis. ACEC will purchase, in accordance with contract clauses, any spare part identified as being required to perform the Work. WE will also be responsible for the preservation of spare parts that are held to ensure their condition is “fit for Work” when required. ACEC will ensure that suitable preservation procedures are in place for this and provide preservation measures for equipment under this scope in accordance with vendor recommendations and requirements.

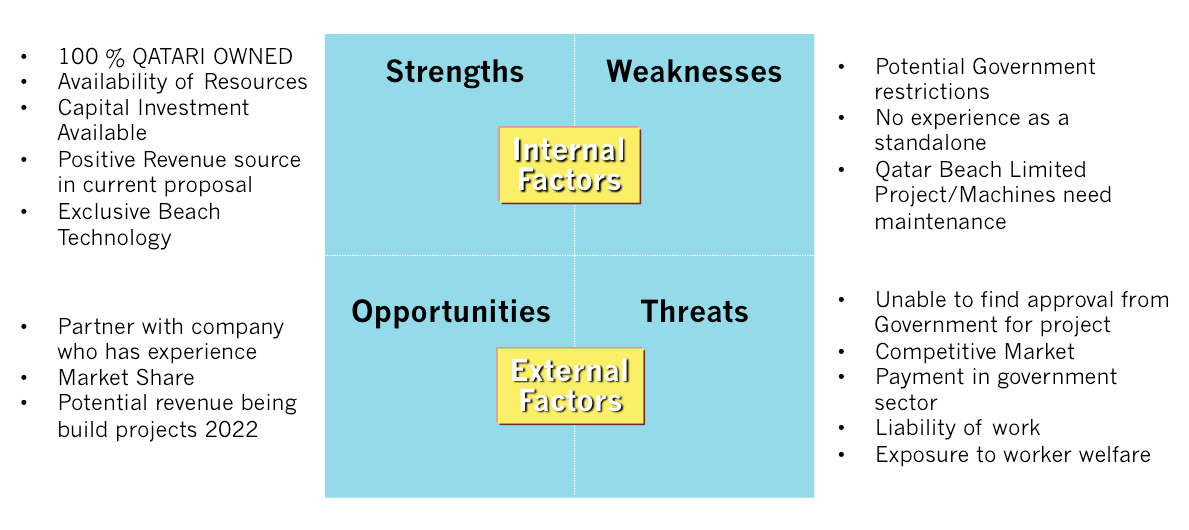

AG: Strengths, Weaknesses, Opportunities, Threats

A SWOT analysis assists in development of supplier selection and negotiation strategies

Current Doha Competitors:

- Sodexo — Teyseer

- Acciona — Nasser Bin Ghanem

- United Facilities Management Company (UFMCO)

- Ownership: — United Development Company (100%)

- Al Asmakh Facilities Management WLL

- Maintenance Management Group Qatar

- Maintenance Management Group Qatar (MMG Qatar) was established in 2006 as a joint venture between MMG Holdings and Al Faisal Holding .

- Coffley Besix Mannai facility management

- SNC-Lavalin O & M — NBK

- AKTOR Facility Management

Potential Partners UAE

- Emrill Integrated Facilities Management

- Khidmah

- Macro — Musanada

- EFS Facilities Services

- Al Shirawi Facilities Management

Scheduling and Cost Control

Scheduling

ACEC will implement a scheduling and cost control system to manage the activities associated with the Work.

Scheduling will include, but will not be limited to the preparation and maintenance of:

- An overall project schedule showing the preparation and mobilization activities for the Work, including the supply management process necessary to put in place all commitments with suppliers and subs for ACEC. Where such commitments are intended to be renewed during the duration of the Work. This will be indicated on the schedule.

- Monthly schedules of activities listed in the scope of Work and planned for performance during the scheduled month

- Weekly activity schedules showing the programmed activities for the scheduled week

Cost Control

ACEC will produce a monthly cost report showing the cost forecast and expenditures accruing against the various parts of the scope of Work. These will be split to show

- Cost forecast and expenditures against agreed scope of Work items

- Cost forecast and expenditures against approved variations to the Work

Technical and Corporate Support

ACEC will provide comprehensive technical support, incorporating engineering support for the utilities and technical systems. This technical support systems must support the maintenance strategy of total productive maintenance (TPM) which focuses on maintaining the overall system function (rather than on the maintenance of individual equipment) whilst taking into account safety, environmental, cost, legislation and reliability requirements of the systems to produce an auditable and balanced maintenance programme.

The comprehensive technical support will include, but will not be limited to:

- Provision of technical and engineering support for preventive and corrective maintenance of utilities systems covered under the scope of work

- Provision of specialist subACECs who are experts in their field or original equipment manufacturers to augment this Work

- Maintain detailed records of all equipment and materials which are under warranty by the original supplier and coordinate with vendors as needed